Expert Juice Bar & Restaurant Fitouts Australia

Turning Your Healthy Vision into a High-Performing Reality

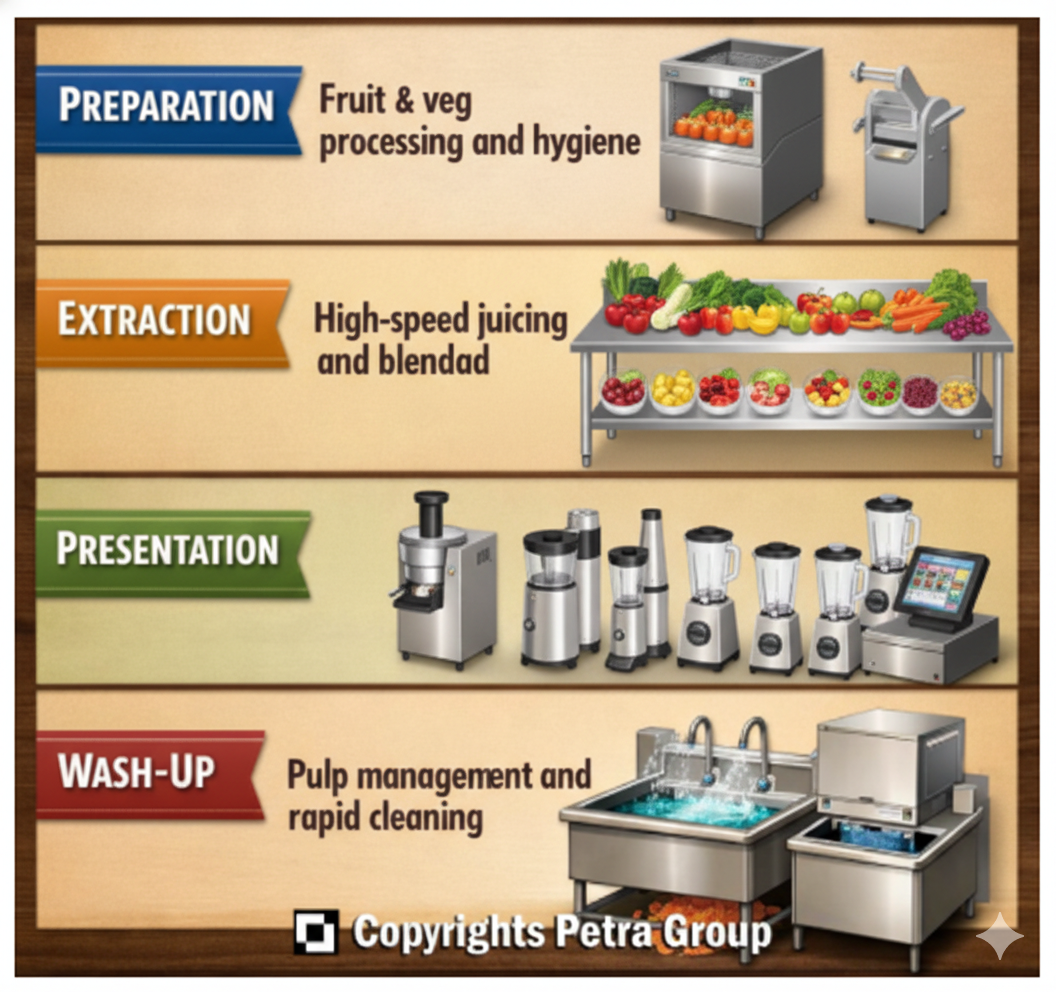

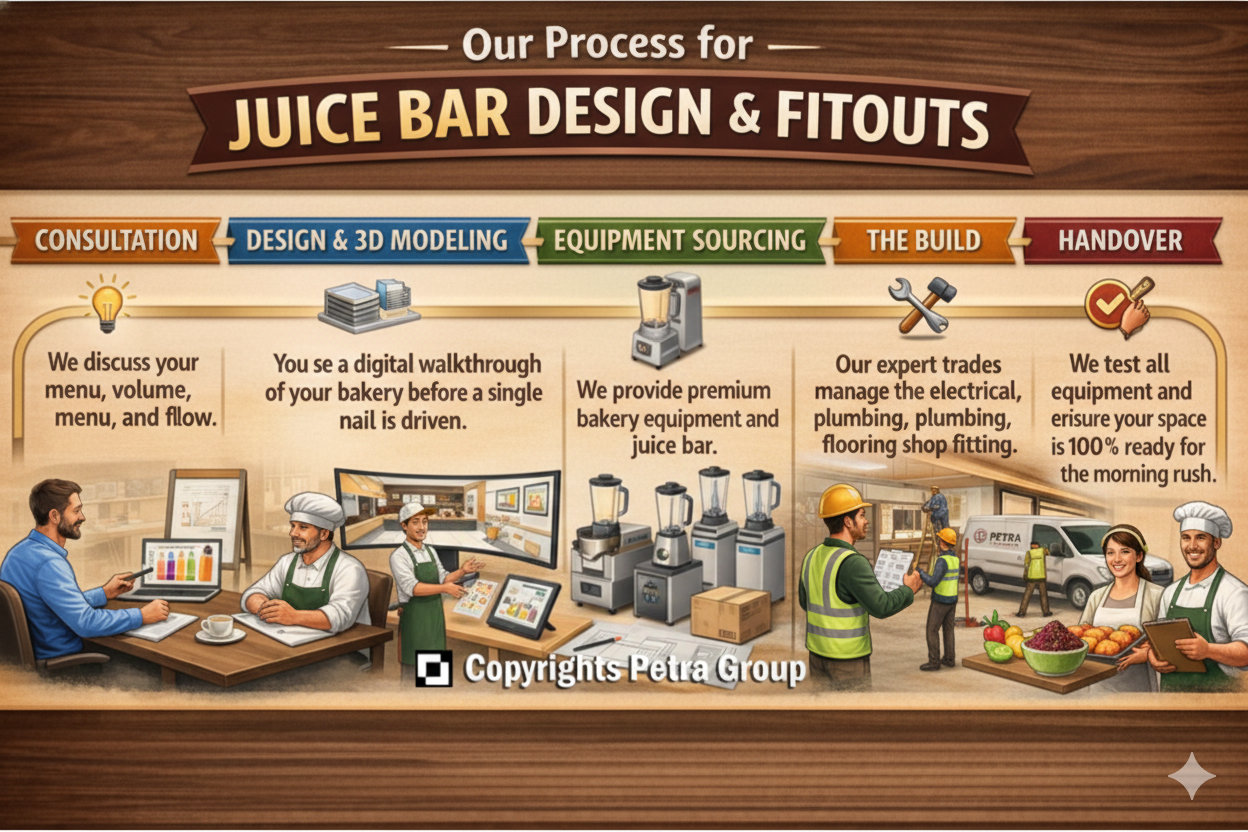

The secret to a successful juice bar isn’t just the perfect blend; it’s a floor plan that flows under pressure. At Petra Group, we specialize in end-to-end juice restaurant fitouts that balance vibrant front-of-house aesthetics with high-speed back-of-house efficiency. Whether you are launching a boutique cold-pressed juice shop or a high-volume commercial smoothie and acai bar, we design spaces that work as hard as you do. Our head office is based in Sydney, feel free to visit us: 5/62 Hume Hwy, Lansvale NSW 2166, Australia.