Expert Japanese Restaurant Design & Fitouts Australia

Turning Your Culinary Precision into a High-Performing Reality

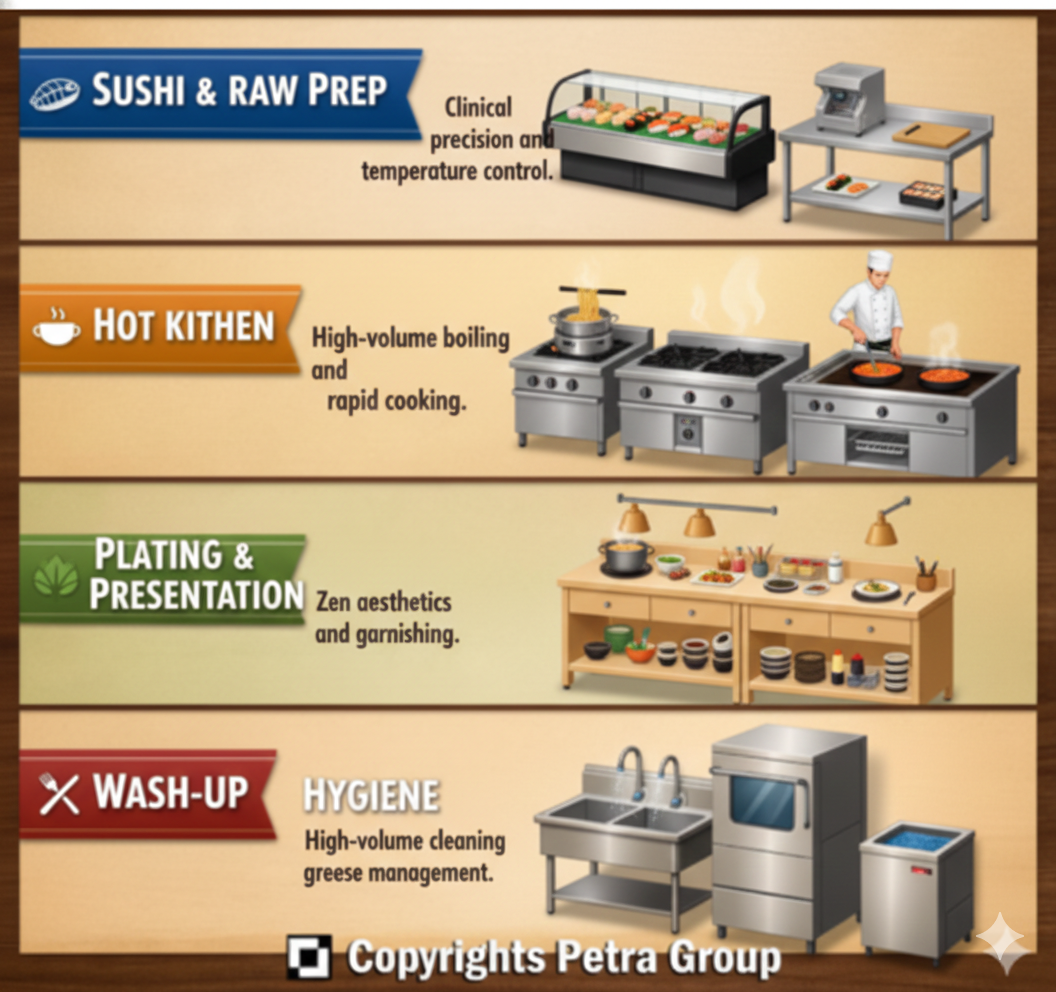

The secret to a successful Japanese restaurant isn’t just the freshness of the fish; it’s a floor plan that flows with Zen-like efficiency. At Petra Group, we specialise in end-to-end Japanese restaurant fitouts that balance minimalist front-of-house aesthetics with high-performance back-of-house kitchen engineering. Whether you are launching an intimate Omakase sushi bar or a high-volume commercial Ramen house, we design spaces that work as hard as you do. Our head office is based in Sydney, feel free to visit us: 5/62 Hume Hwy, Lansvale NSW 2166, Australia.