Expert Indian Restaurant Design & Fitouts Australia

Turning Your Culinary Heritage into a High-Performing Reality

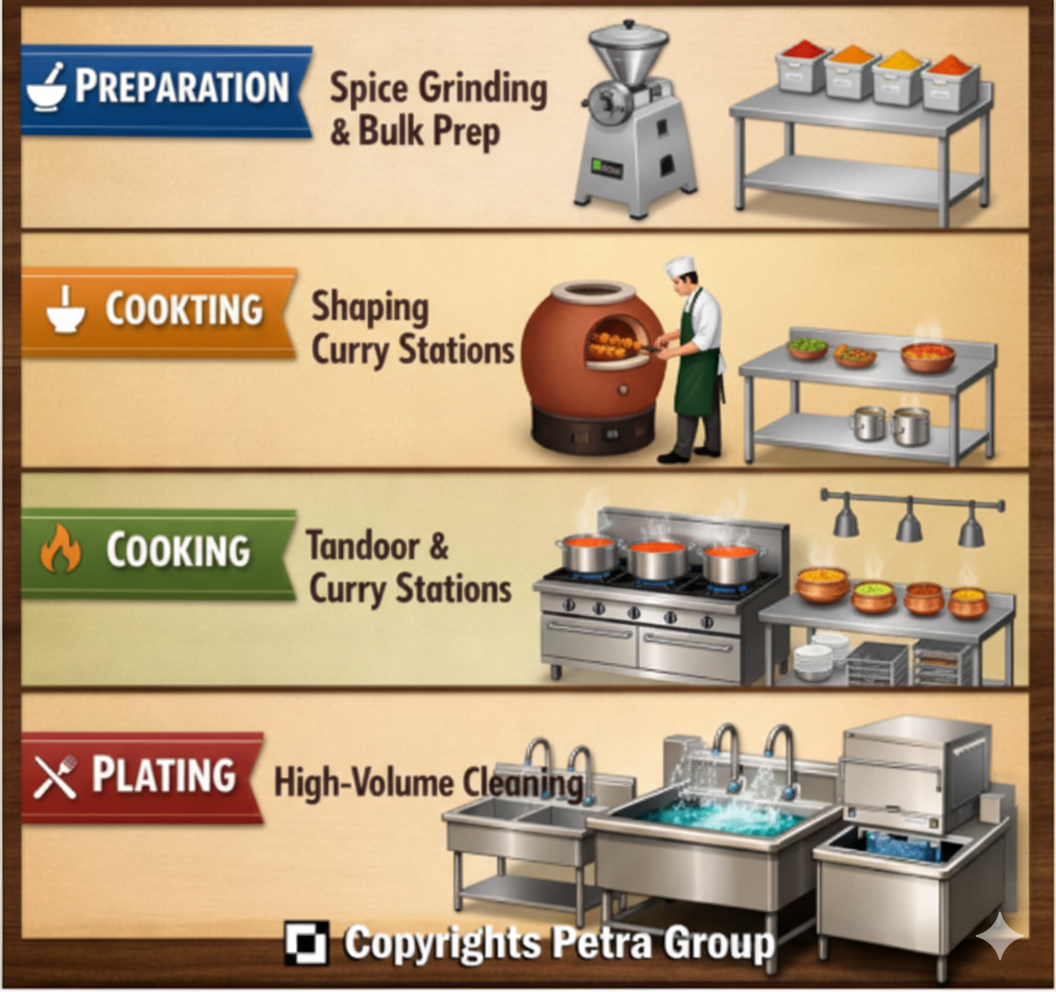

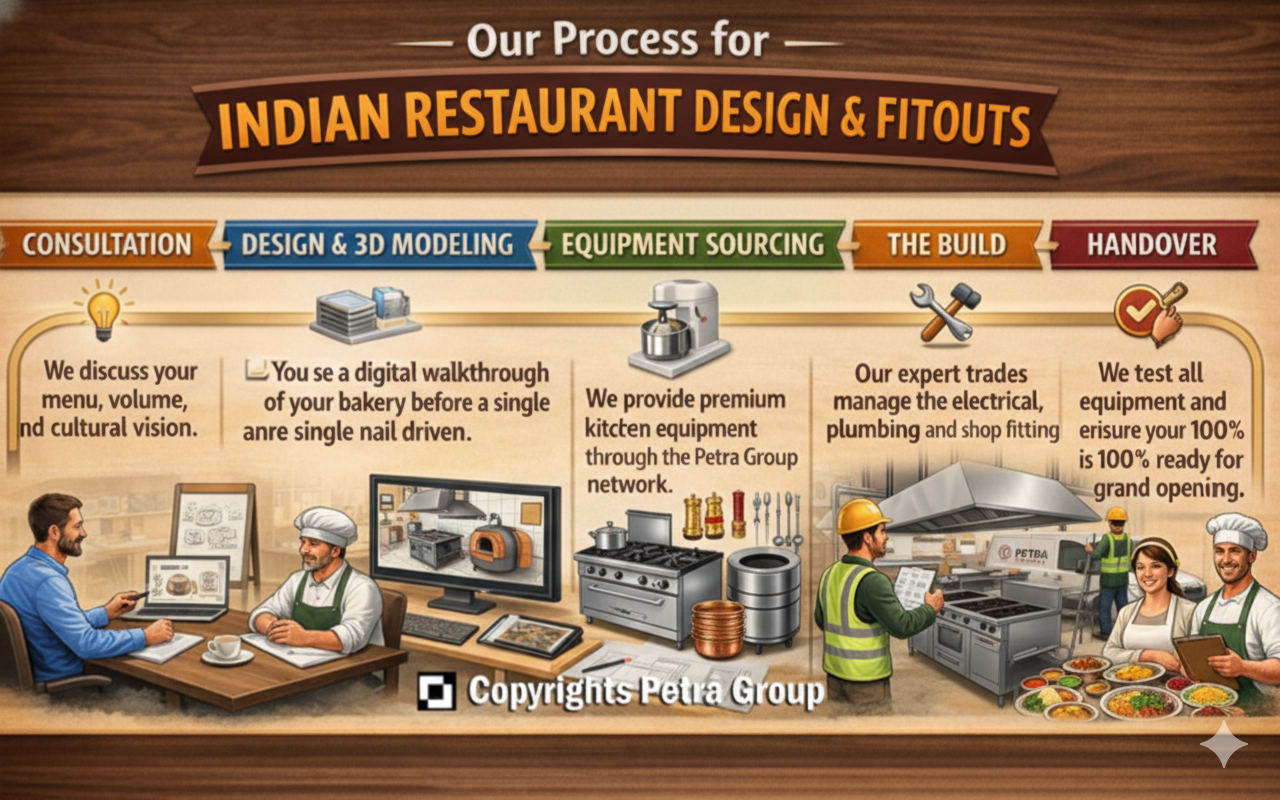

The secret to a successful Indian restaurant isn’t just the perfect blend of spices; it’s a floor plan that flows. At Petra Group, we specialise in end-to-end Indian restaurant fitouts that balance the vibrant aesthetics of the front-of-house with the intense industrial efficiency required in the back-of-house.

From installing high-heat Tandoor stations and heavy-duty ventilation systems to designing elegant dining areas for fine dining, we design spaces that work as hard as you do. Whether you are launching a quick-service chaat hub or a high-end Indian banquet hall, our team understands the unique workflow of subcontinental cuisine.