Expert Ice Cream & Cake Shop Design & Fitouts Australia

Turning Your Sweet Passion into a High-Performing Reality

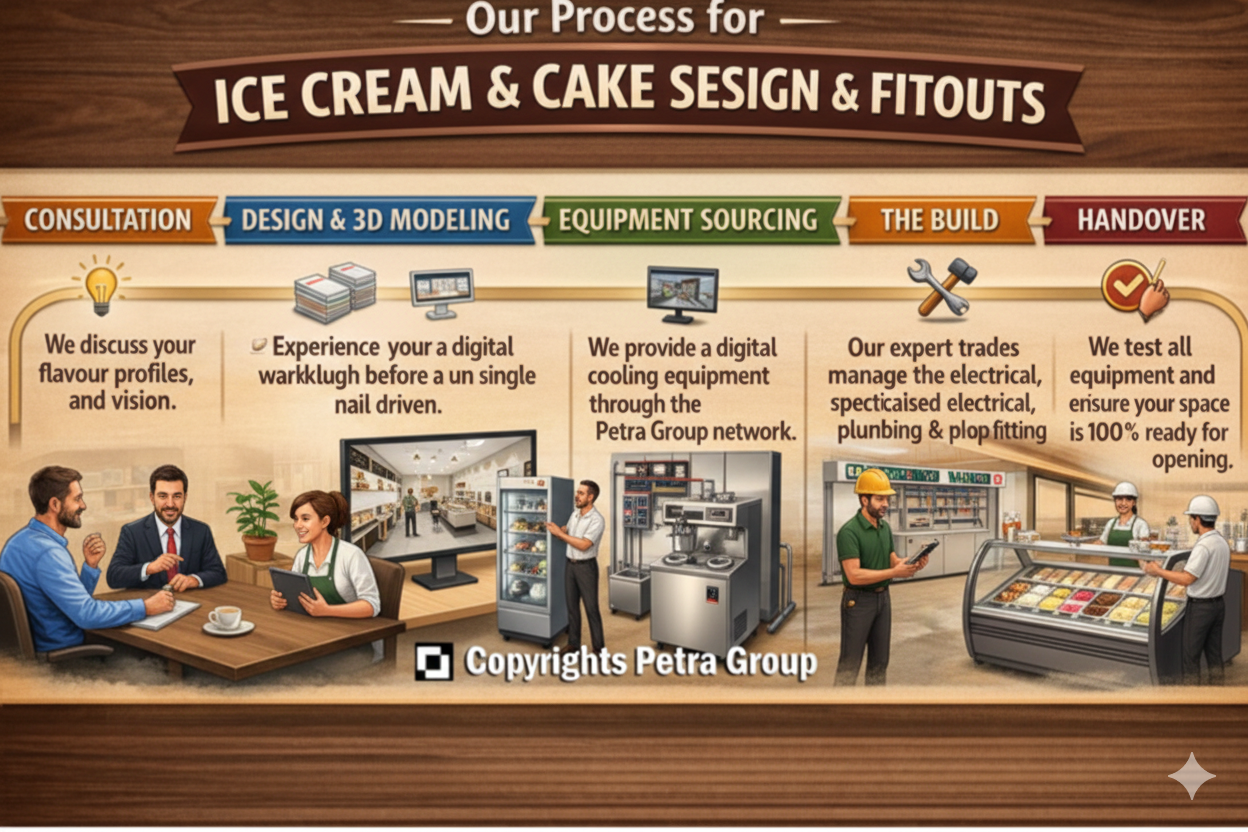

The secret to a successful dessert destination isn’t just the perfect scoop or a flawless glaze; it’s a floor plan that flows. At Petra Group, we specialise in end-to-end ice cream and cake shop fitouts that balance front-of-house “wow factor” aesthetics with back-of-house precision cooling and efficiency.

Whether you are launching an artisanal gelato boutique or a high-volume commercial cake parlour, we design spaces that work as hard as you do. From managing critical temperature zones for delicate pastries to creating the perfect “Instagrammable” seating area, we ensure your business is built for success.